In early January last year, The Indian Express had reported on the health hazards caused by Haryana Power Generation Corporation (HPGC) owned Panipat thermal plant. The story stated that at least one person in each family living in nearby Khukhrana village suffered either from skin diseases or respiratory ailment thanks to air and water pollution caused by thermal power plant. HPGC is a public sector undertaking under Haryana state government, formerly the Haryana State Electricity Board.

A year later, in February 2009, the latest Comptroller and Auditor General (CAG) audit report that contains a detailed performance audit of the plant. It records how Panipat Thermal power station failed to monitor pollution levels and failed to ensure compliance of norms. Scrutiny of the records of Panipat Thermal power station with regard to environmental safeguards and pollution control and monitoring found a plethora of issues:

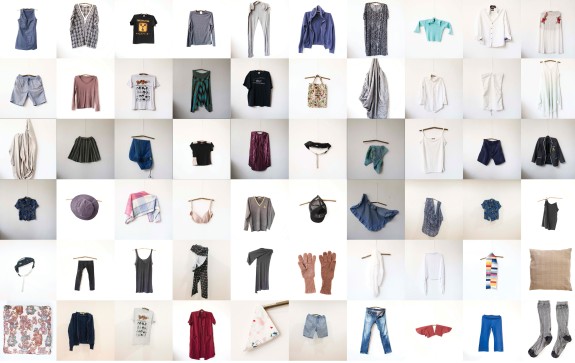

- Deficiency in keeping the concentration of Suspended Particulate Matter [SPM] and Particulate Matter [PM] under the prescribed limit.

- Failure in disposal of 10-12 dumps of mill reject coal that caused frequent fire hazards, an abysmally poor disposal of fly ash produced during 2003-08 even after lapse of more than eight years.

- Failed to develop green belt by the extent of 60 per cent compared to what it committed and targeted for.

The concentration of SPM in ambient air

The concentration of SPM in ambient air, as prescribed by Ministry of Environment and Forests [MoEF] in April 1996 should have been maximum of 500 micrograms per cubic metre. However, the scrutiny of records found that during October 2006 to March 2007 except during March and July 2007 concentration of SPM ranged between 600 to 1494 micrograms per cubic metre.

The CAG has indicted the company for having failed to take effective measures to control the concentration of SPM. This could be done by regular tuning of electrostatic precipitators, proper stacking of crushed coal, proper dumping/disposal of mill rejected coal and making sprinklers functional in coal handling areas.

Further the audit scrutiny noticed that the authorities had failed to provide online monitoring system to record SPM levels in Units I to V. The online monitoring system provided in unit VI was not in working condition and the company was getting monitoring done through outsourcing on a year to year basis, although to provide online monitoring system to record SPM levels is mandatory for thermal power station as per existing environmental governance under Environment Protection Act, 1986.

After this deficiency was pointed out by CAG auditors, the HPGC management responded in August 2008 with this: ..efforts are being made to control the concentration of SPM in ambient air and online monitoring system is being introduced. HPGC's chairman is Ashok Lavasa, and Managing Director is Sanjeev Kaushal.

The concentration of PM

The concentration of PM for thermal power plant should have been maximum of 150 mg per Nm3 (Nm3 is a measure of volume, normal cubic metre, under specific conditions of temperature and pressure), as prescribed by MoEF in May 1993. However, it was found in the audit scrutiny that the PM level of stack emission of units I to IV was higher than the prescribed limit since June 2006 (except in units I and II during August 2006 and for unit II during March 2008) which ranged between 157 and 1276 mg and was the highest at 570 mg in units I and II during April 2007 and 1276 mg in units II and IV in January 2007.

In October 2007, Central Electricity Authority had communicated to authorities its concern over excessive PM level in the stack emission and advised the company to initiate remedial measures to bring down the PM level at stack to or below the prescribed norm.

Not only this, CAG report shockingly notes that mill reject coal was even used for generation at times!

The CAG audit report for the year ending March 31, 2008 also notes that the PM level had not been brought under control till March 2008 and even to this finding the response of authorities in August 2008 was identical, Unit I is under renovation and modernisation and efforts are being made to bring down the PM level of units III and IV.

The use of present continuous tense in the language of these replies being made, being introduced is a giveaway, in the light of the CAG findings. The plant managers have failed to keep pollution under legally enforceable prescribed limits.

Dumps of mill reject coal not disposed

But this is not all. The CAG audit notes that representatives of MoEF, Chandigarh and CPCB, Kanpur during their visit in October 2007 had observed 10-12 dumps of mill reject coal lying around which caused regular fire hazards and asked plant authorities at HPGC to dispose them. However, not only did authorities failed to dispose those dumps, the mill reject coal had accumulated to 2.04 lakh MT as on March 31, 2008.

Not only this, CAG report shockingly notes that mill reject coal was even used for generation at times!

To this observation, plant management replied in August 2008 stating that sale order for disposal of mill reject coal of unit V had been issued and for disposal in remaining units, tenders had been floated. However, this audit findings leaves one wondering whether representatives of MoEF, Chandigarh and CPCB, Kanpur during their visit in October 2007 looked into the SPM level in ambient air and PM level in the stack emission and had there been any follow up on their observation and advise on the matter of disposal of mill reject coal between October 2007 and March 2008.

Similarly, one wonders whether CEA followed up on what action was taken up by plant authorities after its communication in October 2007.

Abysmally poor record on disposal of fly ash

MoEF had notified in September 1999 that brick kilns within a radius of 50 kms around thermal power plant (by a revision in August 2003 this was enhanced to 100 kms radius) would use at least 25 per cent of coal ash on weight to weight basis and thermal power plants were asked to submit an action plan to the Central/State Pollution Control Board and regional office of MoEF by March 2000 for full utilisation of the ash within a period of nine years. Audit scrutiny found that the said report has not been submitted as of March 2008. Audit of the records of ash produced and disposed during 2003-08 revealed that the disposal of ash ranged from 1.80 per cent to 11.26 per cent indicating lack of efforts by the authorities.

To this observation, management replied in August 2008 stating that dry fly ash evacuation system was in the process of installation. Again, note the use if the language in the process of.

Merely 40 per cent plantation in green belt

MoEF had asked the authorities in August 2002 to develop green belt on 44 hectares of land. The audit scrutiny revealed that it took the company 20 months to come out with a scheme of development of green belt [May 2004] in next three year getting 153 thousand [1.53 lakh] trees planted and raised by forest department by spending Rs.1.59 crores. Although the estimated cost was revised to Rs 1.95 crore subsequently, the forest dept could plant just 61,245 trees upto August 2007, there by submitting utilisation certificates for Rs.1.01 crores, as against the advance worth Rs.1.10 crores released to it by the company.

Thus, even after the expiry of three years, the plantation coverage stood only at 40.03 percent. The audit report doesnt give details on field visit observation of the said green belt and survival rates of plantation.

Let us go back to what the one-year-old news item ended with. It had stated, Fed up with lackadaisical attitude of Haryana government and the district administration to the problem, the villagers have formed a Gaon Sudhar Samiti to fight a legal battle in the Punjab and Haryana High Court. It is not clear whether a legal petition has been filed in courts, but can one hope that the judiciary will take suo moto cognizance of this indictment of Panipat thermal power plant.